Sustainability in numbers

At Kärcher, we see the bigger picture. We rely on the strategic aims of several years for the entire corporate group, in order to realise our sustainability vision. We document the achievement of these goals in our sustainability report.

Sustainability report according to GRI standard

Responsibility is an essential part of the corporate culture at Kärcher from the beginning – with sustainable company development focused on people and the environment. Our economic success is based on long-term strategies. This is also the case when it comes to sustainability.

This sustainability report contains Kärcher’s key figures, targets and activities. The report was produced in line with the standards of the current version of the Global Reporting Initiative (GRI).

STRATEGY 2025 MILESTONES

Zero Emissions

22 sites in 8 countries use green energy that has been generated in-house or procured externally.

Absolute carbon emissions were reduced by 16,660 tonnes compared to 2020 with simultaneous company growth.

Scope 3 emissions were analysed fully in 2023 for the first time, including CO₂ emissions of products in the use phase.

Reduce, Reuse, Recycle

All paper-based packaging materials are made from at least 80% recycled paper.

68.8 tonnes of plastic in packaging was saved in 2023 through reduction and by switching from plastic to paper (e.g. polystyrene and bubble wrap).

1,986 tonnes of recycled materials were used in products with a recycled material content of up to 60% in 2023.

Social Hero

82% of all projects are focused on value preservation.

10.23 tonnes of waste were collected during Kärcher Cleanup Day in 19 subsidiaries in 2023.

16 monuments and buildings were cleaned as part of our cultural sponsorship in 2023.

CLIMATE PROTECTION & RESOURCES

Our cleaning machines are the result of a careful use of resources, such as raw materials, energy and water. We establish the basis for this with a production process that fully supports environmental and climate protection. Our specific focus is on reducing the use of virgin plastics, making packaging more environmentally friendly, promoting the use of renewable energies and reducing the carbon emissions we generate.

Energy intensity in TJ per million € of turnover

Greenhouse gas intensity in t CO₂ per million € of turnover

Water intensity in m3 per million € of turnover

Share of recycled waste in %

Waste types

80 %

proportion of recycled paper in paper-based sales packaging

50.000 boxes

from regranulate at the plant in Romania since 2022

> 40 products

in the detergent sector with eco-certification

26 tons

less plastic in packaging at the Ahorn Service Center

11%

of company vehicles are electric

> 1.900 tons

plastic recyclate used in products

Packaging that protects the product and the planet

High-quality packaging ensures our products reach customers safely. Here at Kärcher, however, it's not enough that our packaging just be strong – we believe it should also save resources and be sustainable. And we are working hard to ensure this is the case.

Read onPRODUCTS

Environmental aspects in product design

In our product design, we consistently take environmental aspects, such as resource efficiency and recyclability, into account.

The strategic sustainability aspectsfor each product category are embedded in our product development specifications – including the use of natural substances from food and agricultural waste, the use of recycled plastic, taking reparability and durability into account in the product design, and energy, water and chemical resource efficiency.

The product life cycle is divided into four main areas of focus: material, resources, waste and emissions.

What makes our products sustainable

Produced with low emissions, ecologically conscious material selection, energy-saving and water-saving usage – products for cleaning and care should be sustainable in many ways. Therefore, responsible behaviour at Kärcher includes machine development and the production and supply chain right up to correct disposal – and so does not end at our factory gates.

Read onSUPPLY CHAIN

Our close cooperation with suppliers is crucial for Kärcher’s success. That’s why we want to be a trustworthy and reliable partner to our suppliers and their employees. This also includes taking responsibility for the protection of people and the environment in our supply chain. In light of this, we are continuously further developing our corporate due diligence in the supply chain

Our path to a sustainable supply chain

Sustainability plays a hugely important role at Kärcher – and not just within our own company. We also value environmentally friendly activities, long-term relationships, strict welfare standards and high levels of transparency throughout our supply chain.

Read onPRODUCTION

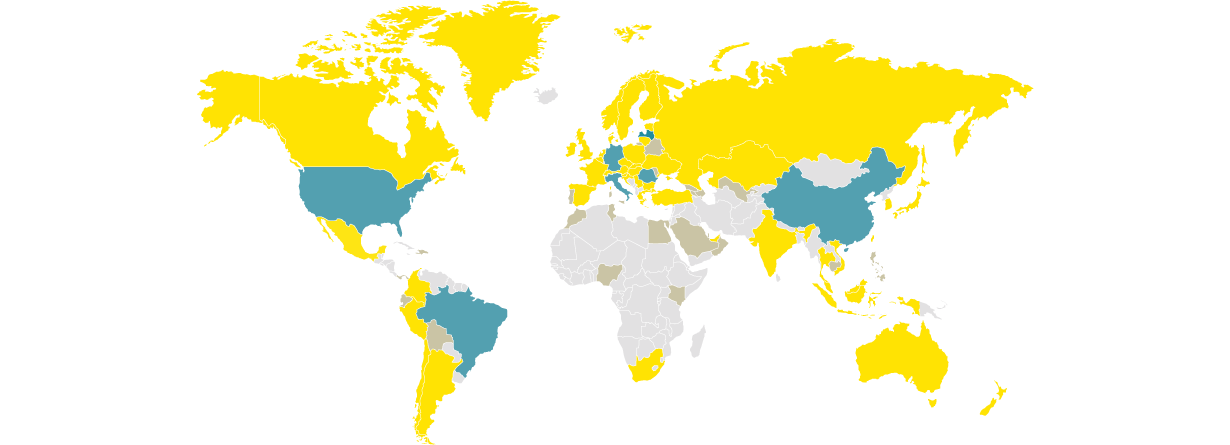

Kärcher sites worldwide

Rooted in Germany – active all over the world: Kärcher produces and sells its products around the globe. The map provides an overview of our worldwide production and logistics sites as well as the approximately 80 countries with sales and service sites.

Countries with Kärcher sales and service sites are highlighted yellow. Countries with Kärcher production and logistics sites as well as sales and service sites are marked turquoise. Countries with Kärcher sales and service sites that are not part of this report are dark grey.

Production and logistics sites

Germany

9001:2015 (Quality)

14001:2015 (Environment)

5001.:2018 (Energy)

45001:2018 (Occupational safety)

Production and logistics sites

Winnenden (Headquarters)

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

Production and logistics sites

Winnenden (Factory)

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

Production and logistics sites

Servicecenter Ahorn

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

Production and logistics sites

Obersontheim (Factory)

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

Production and logistics sites

Obersontheim (Logistic Centre)

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

Production and logistics sites

Bühlertal

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

Production and logistics sites

Illingen

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

Production and logistics sites

Schwaikheim

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

Production and logistics sites

Waldstetten

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

Production and logistics sites

Duisburg

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

Production and logistics sites

Reutlingen

9001:2015 (Quality)

•

14001:2015 (Environment)

5001.:2018 (Energy)

45001:2018 (Occupational safety)

Production and logistics sites

Italy

9001:2015 (Quality)

14001:2015 (Environment)

5001.:2018 (Energy)

45001:2018 (Occupational safety)

Production and logistics sites

Correggio / Reggio Emilia

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

•

Production and logistics sites

Quistello

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

•

Production and logistics sites

Reggio Emilia

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

•

Production and logistics sites

Romania

9001:2015 (Quality)

14001:2015 (Environment)

5001.:2018 (Energy)

45001:2018 (Occupational safety)

Production and logistics sites

Cuerta de Arges

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

•

Production and logistics sites

USA

9001:2015 (Quality)

14001:2015 (Environment)

5001.:2018 (Energy)

45001:2018 (Occupational safety)

Production and logistics sites

Aurora

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

45001:2018 (Occupational safety)

Production and logistics sites

Blackwood (Logistic Centre)

9001:2015 (Quality)

14001:2015 (Environment)

5001.:2018 (Energy)

45001:2018 (Occupational safety)

Production and logistics sites

Fayetteville (Logistic Centre)

9001:2015 (Quality)

14001:2015 (Environment)

5001.:2018 (Energy)

45001:2018 (Occupational safety)

Production and logistics sites

Mexico

9001:2015 (Quality)

14001:2015 (Environment)

5001.:2018 (Energy)

45001:2018 (Occupational safety)

Production and logistics sites

Monterrey

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

45001:2018 (Occupational safety)

Production and logistics sites

Brazil

9001:2015 (Quality)

14001:2015 (Environment)

5001.:2018 (Energy)

45001:2018 (Occupational safety)

Production and logistics sites

Vinhedo

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

45001:2018 (Occupational safety)

Production and logistics sites

China

9001:2015 (Quality)

14001:2015 (Environment)

5001.:2018 (Energy)

45001:2018 (Occupational safety)

Production and logistics sites

Changshu

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

•

Production and logistics sites

Latvia

9001:2015 (Quality)

14001:2015 (Environment)

5001.:2018 (Energy)

45001:2018 (Occupational safety)

Production and logistics sites

Jelgavas Novads

9001:2015 (Quality)

•

14001:2015 (Environment)

•

5001.:2018 (Energy)

•

45001:2018 (Occupational safety)

EMPLOYEES

Number of employees (headcount)

Sustainable HR management

Kärcher pursues a globally valid human resources strategy. This is the responsibility of the central HR Management team in the head office at the Winnenden site and is implemented in collaboration with the HR departments of the subsidiaries. With this strategy, we are pursuing the goal of at tract ing new talented employees, retaining employees in the long term and developing them in a targeted manner. In this context, we take the employee ex perience of our workforce seriously. With our sustainable HR strategy, we want to meet the challenges of a shortage of specialists and demographic change while also ensuring our competitiveness. In doing so, we are working to establish global standards and promote cooperation be tween the individual sites.

Continuous development

Kärcher’s ambition is to attract new, talented professionals and to fully utilise the potential of existing employees. In doing so, we build on our training pro grammes, which have grown over the years, and on a standardised talent management process in conjunction with targeted further training. In this way, we drive the establishment and development of the necessary future com petencies – based on the Kärcher competency model.

85 %

participation in the last global employee survey

46. place

in Forbes' "World's Best Employers" ranking (10th place in Germany)

2,5 days

for training programs at the head office per person

5 %

Training quota at the head office

> 100 ideas

for more sustainability in Brazil in an ideas campaign

726

sustainable travel days for the Kärcher Industrial Vacuuming sustainability challenge

Equal opportunities and diversity

At Kärcher, everyone should be able to develop their own potential – regardless of gender, age, nationality, physical and mental abilities, social background, sexual orientation or religion and ideology. We are proud of the fact that people from 116 nations work together successfully at Kärcher in more than 80 countries. Diversity strengthens our collaboration, our understanding of our customers’ needs and our innovative strength. In order to underpin our commitment to a diverse workforce, we embedded the issue of diversity and inclusion in our Corporate Guiding Principles (mission statement) in 2021.

Statement by the Board of Management

"At Kärcher, we make an impact through our behaviour, our way of treating others and lived diversity. It is the different perspectives, the expertise, and the skills of our employees in more than 80 countries that make a difference. Because only those who focus on looking at the diverse needs and problems of their customers are going to show them solutions that not only offer the best possible cleanliness but also contribute to the preservation of values. Diversity and inclusion bring our company culture to life. They take our company and especially our community a lot further."

SOCIAL COMMITMENT

At Kärcher, we are aware of our social responsibility. That’s why we support non-profit initiatives and organisations that make a significant contribution to society and stand for values such as family, education and equal opportunities as well as the protection of the environment and resources. In all three areas – donations and sponsorship, long-term cooperation and employee commitment – we take our role as a social stakeholder seriously and are therefore dedicated to preserving values, whether social or ecological. That’s why value preservation is also the focus of our “Social Hero” initiative – one of the three pillars of our 2025 Sustainability Strategy.