Applications

Tank interior cleaning is usually complex and can be subject to specific factors: tank size and geometry, typical contamination, external influences. Kärcher system solutions are designed to take all of these factors into account. Convincing examples are:

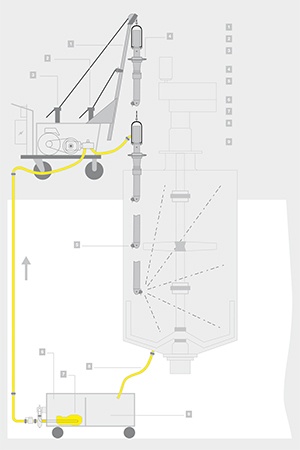

Tank and silo cleaning without limits.

Tank and silo interior cleaning processes are carried out precisely and automatically. While the operator works with specially selected spray heads, the Kärcher system control regulates the interaction of the perfectly matched components: efficient high-pressure pumps, hot water/steam boilers and versatile accessories. Combined in modular system solutions for virtually all applications: cold, warm, hot - acidic or alkaline - steaming and drying.

Perfection in combination – 20-foot containers.

Cleaning containers in combined rail-sea-road transport requires efficient and reliable cleaning systems. This logistics system is demanding due to its far-reaching network and short turnaround times.

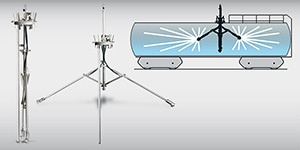

On the right track – tank wagon cleaning.

Tank wagon cleaning systems must meet particularly high interior cleaning requirements due to the size of the wagons and external conditions. Kärcher has extensive tank wagon cleaning application and process expertise. Together with a unique service network, the highest customer requirements are consistently met.

Clean any size perfectly - IBC.

The cleaning and reuse of IBC containers offers convincing advantages compared to single use. Cleaning is more efficient and due to the large number of IBCs in the economic cycle makes a valuable contribution towards protecting the environment. Kärcher offers cleaning stations for all container sizes and content materials.

Ideal for lightweight barrels.

Kärcher barrel cleaning stations are ideal for quickly cleaning lightweight barrels up to a diameter of 750 mm, regardless of their shape. The wash bay with cleaning heads and circulation tank is preassembled and ready to use.

Container cleaning in the chemical industry.

The chemical industry has the broadest spectrum of cleaning applications. It has a particular demand for individual solutions due to the variety of different processes and substances. These range from special cleaning procedures for paints and solvents in the paint industry through to explosion protection according to ATEX 94/9.

Safe cleaning of reactors.

Reactor cleaning is a special application for semi-stationary containers in the chemical industry. Professional, automatic cleaning integrated in the relevant processes is a basic precondition for required reactions occurring under defined conditions. The cleaning of polysilicon process vessels is a forward-looking technology in which Kärcher plays a leading role.