Dry ice cleaning

Everything for a clean industry In the area of industrial cleaning systems, Kärcher offers innovative and advanced solutions for all requirements. The range includes high-pressure cleaners, industrial vacuums, tank and parts cleaning systems as well as dry ice cleaning machines.

Impeccable cleanliness

Soiled moulds, parts or machines are often difficult to clean. The problem: sandblasting can leave spray agent such as sand or glass granulate. This often means having to clean after cleaning. This is no longer necessary with the high-performance ice blasters from Kärcher. After blasting, the dry ice pellets dissolve completely into carbon dioxide (CO2). The result is perfect cleanliness.

Advantages of dry ice blasting

- No preparation required prior to cleaning

No need to disassemble machines for cleaning. The pellets easily reach into even the smallest nooks and crannies.

- Minimal machine downtimes

thanks to fast and effective cleaning with dry ice.

- Environmentally-friendly cleaning

without additional chemicals or spray agents.

- Surfaces are not damaged

- No residues

Dry ice sublimates completely to CO2. There are no residues such as abrasives or waste water.

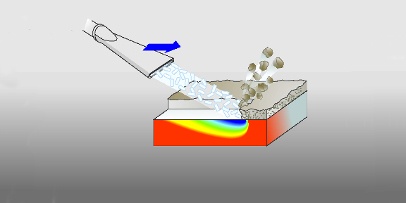

Cleanliness = cold x velocity

The ice blaster uses compressed air to propel the 3-mm dry ice pellets to the high velocity of over 150 m/s. The cold temperature of -79°C freezes the dirt and causes it to crack. The dry ice pellets ejected at a high speed can then remove the dirt easily. This is an especially effective method of gently removing virtually all types of dirt.

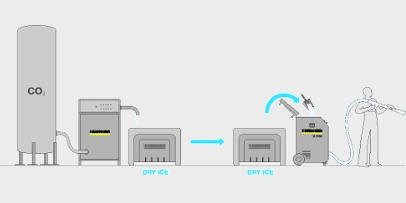

From carbon dioxide to ice

During the production process, liquid carbon dioxide flows into the pressing cylinder of the pelletizer and is turned into dry ice snow by the pressure drop. A hydraulic cylinder compresses this dry ice snow, which is then pressed through an extruder plate. This causes rods of dry ice to form, which are then broken down into pellets.

Cleanliness in all areas.

Kärcher Ice Blasters do not use any cleaning agents or chemicals. They are suitable for use in all areas where cleaning with water or sand is legally prohibited. Because the pellets dissolve without residues, no waste water is produced. The dry ice pellets can easily be self-made with the aid of the high-performance Kärcher dry ice pelletiser.

Steel, metal and machine construction

Deep cleaning and maintenance cleaning of production machinery, welding robots, conveyor belts and paint shops is extremely easy with Ice Blasters from Kärcher.

Printing plants

After dry ice blasting, all printing machines and cylinders, tools, etc., look like new.

Timber and electrical industry

Dry ice blasting is also ideal for cleaning woodworking machines, generators, turbines, control cabinets, etc.

Plastic and packaging industry

The dry ice blaster removes silicone and rubber as well as dyes, paints and other dirt from injection moulds and production lines.

Automotive industry, foundries and plastic injection moulding plants

Our dry ice cleaners remove binding and parting agents from all kinds of parts and workpieces. Residues such as silicone, rubber, dyes, paints, parting agents, etc., can easily be removed from injection moulds, tools and entire production lines. Cleans perfectly without leaving residues.

Food, pharmaceutical and cosmetics industry

An ice blaster is ideal for removing coking, burnt-in deposits, encrustations, fat and starch from filling and mixing plants, production lines, handling systems as well as tanks and furnaces.

Paper industry

In the paper industry, glue, lime, dust and cellular materials are deposited in the systems. Machine downtimes and loss of quality are the result. Systems are cleaned faster with dry ice and are soon ready to use again.

Local authorities and municipalities

Graffiti and chewing gum: a problem for many cities and municipalities. This calls for a cleaning method that cleans walls and surfaces thoroughly, yet gently – like ice blasters from Kärcher. They remove dirt without damaging surfaces.

Self-made dry ice.

With the Kärcher pelletiser, making your own dry ice pellets is easy: it allows you to avoid waiting times and save money on purchasing and transporting new pellets. Cleaning with freshly made dry ice can cut cleaning times by half under ideal conditions. The fresher the pellets, the better the cleaning result. The option of making dry ice when needed makes cleaning more efficient.

Kärcher pelletisers, IP 55, IP 120 and IP 220, are ideal for all dry ice pellet quantities. The dry ice produced with Kärcher pelletisers can be used for cooling heat-sensitive products (e.g. in the food industry).

The Kärcher dry ice box for transport and storage of dry ice pellets is available in two variants: as a disposable polystyrene box for up to 25 kg of dry ice and as a reusable box made from expanded polypropylene (EPP) for up to 100 kg of dry ice. The reusable box offers good insulation, is lightweight and durable.

How important is the quality of the dry ice?

Experience has shown that cleaning is much faster and more effective with freshly produced dry ice pellets. That's why it is essential to use dry ice that is as fresh as possible for dry ice blasting.

Dry ice that is several days old loses density and this diminishes the cleaning performance. As a result, more dry ice is required to clean a given area. Moreover, dry ice is continuously sublimating, which means that a quantity of dry ice pellets that originally weighed 100 kg will only weigh around 92 kg after one day.

Environmental compatibility of dry ice blasting.

No harmful substances

No toxic or environmentally harmful chemicals or solvents are used in dry ice blasting. This means that no toxic or harmful vapours are released, and there is therefore no risk to employees from using hazardous substances that are harmful to health.

Easy disposal

No spray agent is left over in dry ice blasting. The dislodged dirt falls to the ground and can be swept up. Only the dirt that is generated as a result of the cleaning procedure needs to be disposed of. By contrast, chemicals and solvents that are used for cleaning create hazardous waste that is difficult to dispose of.

No secondary waste

In sand-blasting, soda-blasting and water-blasting, the blasting substance itself generates hazardous waste if it has been used to remove hazardous dirt. A very large quantity of secondary waste is produced, which in some cases must be disposed of with great care and at considerable cost.

Carbon dioxide production

CO2 is a by-product of other industrial production processes. Carbon dioxide is produced, for example, from CO2 scrubbing in ammonia and methanol synthesis. A large proportion of the CO2 used is generated from raw carbon dioxide produced as a waste gas in the chemical processing of crude oil and gas. Carbon dioxide is also produced by combustion processes in power stations and in fermentation processes.

That's why CO2 no longer needs to be specially produced in industrialised countries, and burning fossil fuels to generate CO2 is now a thing of the past.

Safety equipment.

The following protective gear is necessary for dry ice blasting.

Hearing protection

Since the noise level generated by dry ice blasting can sometimes exceed 85 dB(A), hearing protection must be worn.

Gloves

Gloves are recommended to protect against frostbite from the dry ice pellets.

Safety goggles

Wearing safety goggles is recommended to protect eyes from particles that are flying around. We also recommend a complete safety system consisting of helmet, visor and hearing protection.

Breathing apparatus

Depending on the quantity of dust produced or the concentration of CO2, light or even heavy-duty breathing apparatus may be required.

Carbon dioxide detector

Personnel involved in blasting procedures should wear a CO2 detector in order to detect the concentration of CO2 in the surrounding air. This will alert the wearer as soon as a critical concentration is reached.