Hot water high-pressure cleaners: Fighting viruses, germs and bacteria with high pressure and heat

Intensive and meticulous cleaning with hot water high-pressure cleaners makes it possible to achieve high standards of hygiene. Not only can places be reached that are difficult to access manually, these machines are particularly useful for cleaning and disinfecting large areas such as ceilings, walls and floors, and are effective in combating germs, bacteria and viruses.

Advantages of hot water high-pressure cleaners

The use of hot water high-pressure cleaners accelerates the cleaning by up to 40 per cent compared with cold-water machines on account of the faster drying process for the clean surfaces. With the use of hot water high-pressure cleaners, work is carried out with a water temperature of up to 85 °C. When the steam stage is used, cleaning can even be performed with temperatures of up to 155 °C.

In addition to the better results and faster cleaning and drying times, hot water high-pressure cleaners are a great advantage thanks to their germ-reducing effect, in particular in hygiene-sensitive areas such as animal sheds in agriculture, in large kitchens or in the food industry.

Disinfectant effect: Heat as a key factor for greater hygiene

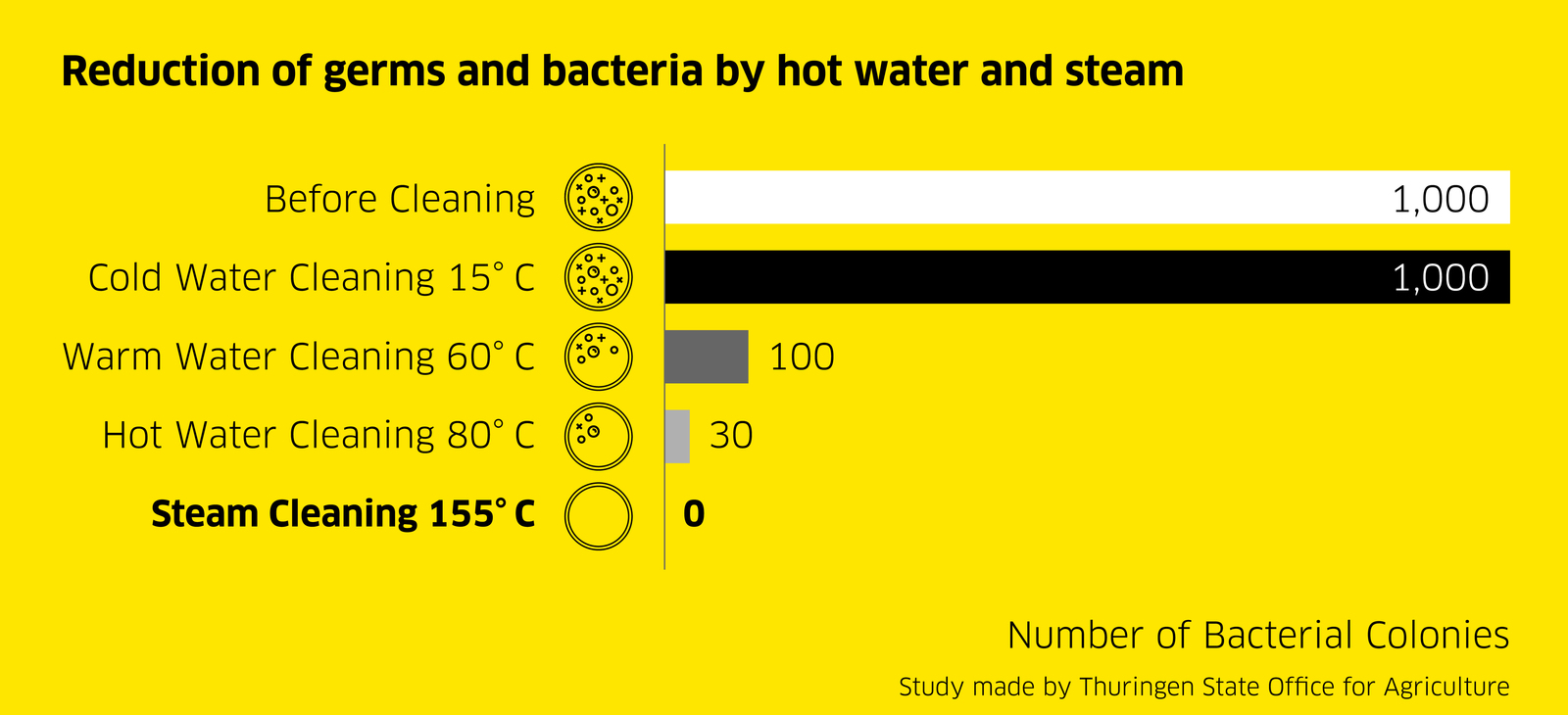

The use of cleaning agents and disinfectants plays an important role in cleaning processes. But what many people do not know is that hot water also makes a significant contribution to fighting disease-carrying germs. With the use of high-pressure cleaners, the water temperature has a significant effect on the reduction of germs, as well as viral and bacterial colonies. Thanks to the combination of high pressure and the hot water at a temperature of up to 85 °C, a substantial reduction of contamination is achieved. This germ reduction is often sufficient without the use of disinfectants in order to satisfy hygiene requirements. In order to support the effect of hot water, the addition of disinfectant by the high-pressure cleaner is recommended.

Heated high-pressure cleaners are especially suitable in areas where maximum hygiene is required and micro-organisms and contamination are targeted during cleaning. This applies not only in the food sector – from the artisan butcher to large-scale industrial production – but also in agriculture, where it essential to pay attention to cleanliness in milking parlours or to prevent animal diseases. Also for the cleaning of public places, in train stations or playgrounds, users can benefit from the efficacy of hot-water machines.

Products

Certification for Kärcher hot water high-pressure cleaners

Within the framework of a quantitative suspension test, the viral reduction capacity of Kärcher high-pressure cleaners with a hot water function was evaluated in an independent laboratory. A test with comparable parameters was reconstructed without the application of a hot water high-pressure cleaner, and, using a simulated temperature profile, the efficacy of the machines at different temperatures on various test viruses was validated.

The result: Already from a water temperature of 65 ° C – when applied to a contaminated surface – and with a contact time of under one minute, enveloped viruses such as corona, influenza, ebolavirus and hantavirus can be effectively reduced. Non-enveloped adenoviruses are effectively fought from 75 °C and a with contact time of less than five minutes.

The disinfectant effect is thus proved and the machines are classified as "limited virucidal PLUS" in accordance with the effective range defined by the Robert Koch Institute. This designation applies to products that can deactivate all enveloped viruses, such as corona, influenza or HI viruses, as well as the non-enveloped adeno-, rota- and noroviruses. The effectiveness thus covers the viruses that are particularly often responsible for disease outbreaks.

Super Class hot water high-pressure cleaners

Whether on construction sites or in stables, removing stubborn dirt requires maximum performance. This is exactly what our Super Class hot water high-pressure cleaners provide. The high-end variants boast first-rate accessories and ergonomic handling, while the Classic machines focus on ultra-simple operation and a robust design. Stand up to dirt – with up to 200 bar of pressure and a flow rate of 1300 l/h.

Middle Class hot water high-pressure cleaners

Cleaning on construction sites or in agriculture is hard work. Our Middle Class hot water high-pressure cleaners are designed to do just that. They either come with first-rate accessories and ergonomic handling or with a focus on ultra-simple operation and a robust design – depending on requirements. In any case, they always offer high quality and maximum performance – with max. 210 bar of pressure and a flow rate of 1000 l/h. These are the new Middle Class machines.

Compact class

Carry out vehicle cleaning and engine washes or remove dirt from outside stairs. With hot water high pressure up to 180 bar and 900 l/h. This is the new compact class.

Upright class

These powerful and robust machines stand out due to their manoeuvrability and easy transport. This makes the upright class an economical alternative for diverse workshops, small garages and cleaning service providers.

Special class

When exhaust gases are to be avoided or prohibited: the special class with electric heating is used in hygiene areas, hospitals, canteen kitchens or public baths.

Combustion engine

Where there is no power source, high pressure cleaners with combustion engine – with optional biodiesel operation – offer maximum versatility and independence.

Cleaning agents

For cleaning with high-pressure cleaners, additional suitable cleaning agents should be applied with the cup foam lance in order to interrupt infection chains and remove all dirt residues. One advantage of cleaning foam is that it is so stable that it adheres to surfaces, thus increasing the contact time and cleaning power. The subsequent flushing with water helps to carry the dirty away in a controlled manner, thus preventing renewed contamination. Bio-degradable cleaning agents can further support this process. In addition, it is necessary to alternate between acid-based and alkaline foam cleaning products in order to remove the basis of life for micro-organisms.